佳味添成:专业开发北冬虫夏草保健茶饮料:从原料到落地的全流程指南

在健康消费浪潮席卷全球的当下,功能性保健饮品成为市场新宠。北冬虫夏草(蛹虫草)凭借其与天然冬虫夏草相媲美的药用价值,正逐步成为食品饮料行业创新研发的焦点。佳味添成将系统解析如何以科学方法开发一款兼具功效与口感的北冬虫夏草保健茶饮料,涵盖从原料筛选、工艺优化到产品落地的完整研发链条。

一、原料体系构建:多维功能成分的协同设计

1、 Construction of Raw Material System: Collaborative Design of Multi dimensional Functional Components核心原料的深度挖掘

Deep excavation of core raw materials北冬虫夏草富含虫草素、虫草多糖、D-甘露醇等活性成分,具有调节免疫、降血糖血压等潜力12。研发团队需建立严格的菌种筛选标准,优选高产活性成分的菌株,并通过液体发酵技术实现标准化生产。例如,采用蔗糖、黄豆粉为碳氮源的培养基,在pH7.0、温度25℃条件下发酵,可使菌丝体湿重达较高水平1。同时,需引入紫外分光光度仪、高效液相色谱等设备,对虫草素等关键指标成分进行定量检测,确保原料质量稳定性12。

复合茶基的风味与功能平衡

The flavor and functional balance of composite tea base为解决单一虫草提取液可能存在的感官缺陷,需构建多茶种协同体系:

To address the potential sensory defects of a single cordyceps extract, it is necessary to construct a multi tea collaborative system:

甜茶:广西特产甜茶提供天然甜味,其甜叶菊甙含量可达高甜度且低热量,兼具清热润肺功效,可替代传统糖源,特别适合糖尿病人群12;

Sweet tea: Guangxi specialty sweet tea provides natural sweetness. Its stevioside content can reach high sweetness and low calorie. It has the effect of clearing away heat and moistening the lungs, and can replace traditional sugar sources, especially suitable for diabetes people; 12;苦丁茶:含苦丁甙元、熊果酸等成分,赋予饮料清爽口感的同时,发挥降血脂、抗动脉硬化作用,但需控制添加量以避免过度苦涩12;

Kuding tea: contains ingredients such as Kuding glycosides and Ursolic acid, which give the beverage a refreshing taste while also exerting lipid-lowering and anti arteriosclerosis effects. However, the amount added should be controlled to avoid excessive bitterness;茉莉花茶:通过低温浸提保留挥发性香气成分,其芳樟醇等物质能提升饮料层次感,同时疏解情绪的功效与虫草的镇静作用形成协同12。

Jasmine tea: By low-temperature extraction, volatile aroma components are retained, and substances such as linalool can enhance the layering of the beverage. At the same time, the effect of relieving emotions is synergistic with the sedative effect of cordyceps.辅助成分的功能性强化

Functional enhancement of auxiliary components参考专利配方,可添加柠檬酸(0.2%-0.4%)调节pH至酸性范围,既抑制褐变又增强风味鲜活度;蜂蜜(1%-2%)作为天然防腐剂和增稠剂,与虫草多糖形成保湿体系,延长货架期45。值得注意的是,针对特殊人群如糖尿病患者,可采用甜茶提取物完全替代砂糖,实现“无糖化”设计2。

二、工艺技术攻坚:关键环节的参数优化

2、 Process technology breakthrough: parameter optimization of key links茶叶浸提的精准控制

Accurate control of tea extraction不同茶种的特性差异要求差异化浸提方案:

The characteristic differences of different tea varieties require differentiated extraction schemes:

甜茶:茶水比1:30、80℃浸提20分钟,透光率可达94.6%,保留甘甜本味1;

Sweet tea: Tea water ratio of 1:30, extracted at 80 ℃ for 20 minutes, with a light transmittance of up to 94.6%, retaining the sweet and natural taste of 1;苦丁茶:1:15茶水比、90℃处理30分钟,可溶性固形物含量达7.1%,兼顾有效成分溶出与苦味适度1;

Kuding tea: 1:15 tea to water ratio, treated at 90 ℃ for 30 minutes, with a soluble solids content of 7.1%, balancing the dissolution of active ingredients and moderate bitterness;茉莉花茶:低温(70℃)、短时(20分钟)浸提结合动态萃取技术,最大限度保留挥发油成分,香气值提升30%以上1。

Jasmine tea: Low temperature (70 ℃), short-term (20 minutes) extraction combined with dynamic extraction technology, maximizes the retention of volatile oil components, and increases aroma value by more than 30%.所有浸提液均需经硅藻土过滤和膜分离技术去除杂质,确保澄清度符合GB/T 21733标准。

All extraction solutions must undergo diatomaceous earth filtration and membrane separation technology to remove impurities and ensure clarity in accordance with GB/T 21733 standard.虫草发酵的工业化转化

Industrial transformation of cordyceps fermentation采用三级发酵工艺:母种活化→三角瓶种子培养→发酵罐扩大培养。关键参数设置为:接种量5%、摇床转速180rpm、温度25±1℃,发酵周期约7天。当蔗糖利用率达到一定阈值时终止发酵,此时虫草多糖含量最高1。发酵结束后立即进行高压均质处理,使菌丝体破碎率>90%,释放胞内活性成分1。

调配与灭菌的技术突破

Technological breakthroughs in blending and sterilization通过正交实验确定最佳配比:甜茶浸出液30%、茉莉花茶浸出液20%、苦丁茶浸出液3%、虫草发酵液30%,并添加0.05%维生素C抑制非酶褐变1。调配后的半成品需经过两阶段杀菌:先经超高温瞬时灭菌(135℃/5s),再灌装至无菌容器中二次灭菌(80℃/20min),既能保证商业无菌又最大限度保留热敏性成分45。

三、质量控制体系:从实验室到量产的标准化路径

3、 Quality Control System: Standardization Path from Laboratory to Mass Production感官评价体系的构建

Construction of sensory evaluation system组建由食品工程师、调酒师、中医专家构成的评审团队,制定量化评分表:组织状态(清亮透明计40分)、香气(复合香型强度计30分)、口感(甜苦平衡度计20分)、色泽(浅红褐色均匀度计10分)。定期开展双盲测试,确保批次间一致性1。

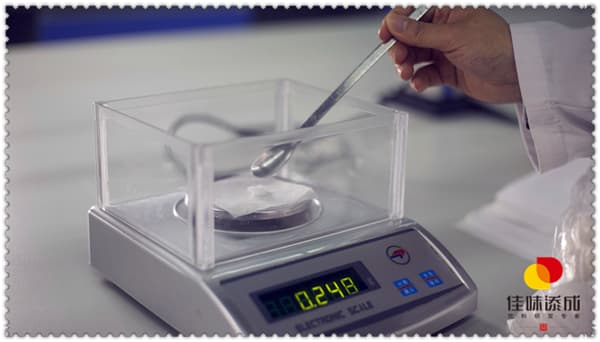

理化指标的在线监测

Online monitoring of physical and chemical indicators配置手持糖度计、pH计、色差仪等便携设备,实时监控可溶性固形物(8%-12%)、总酸(以柠檬酸计≥0.3g/100mL)、L*值(亮度≥45)等关键参数。每批次留样保存于加速试验箱(37℃/RH75%),模拟保质期内的营养成分衰减曲线。

安全性评估的双重保障

Dual guarantee of security assessment除常规微生物检测(菌落总数≤100CFU/mL、大肠菌群≤3MPN/100mL)外,还需进行重金属(铅≤0.5mg/kg)、农药残留(六六六≤0.2mg/kg)筛查。针对虫草特有的腺苷成分,建立HPLC特征图谱,确保标志性成分含量波动幅度<±10%。

四、产业化落地策略:从样品到商品的转化要点

4、 Industrialization Implementation Strategy: Key Points for Conversion from Samples to Commodities生产设备选型的经济性分析

Economic analysis of production equipment selection中小型生产线建议选用模块化组合设备:发酵系统采用不锈钢生物反应器(容积500L),浸提工序配置智能温控提取罐,灌装线匹配全自动负压灌装机(产能≥2000瓶/小时)。整套设备投资较进口方案降低40%,且便于清洁验证12。

包装设计的功能性创新

Functional innovation in packaging design推荐使用PETG材质广口瓶,配合铝箔垫片密封,透氧率控制在较低水平。标签标注“每日饮用量≤300mL”“不适宜人群:孕妇、婴幼儿”等警示信息,符合《食品安全国家标准 预包装食品标签通则》要求。外盒采用再生纸浆模塑,体现环保理念。

市场定位与法规合规

Market positioning and regulatory compliance聚焦亚健康人群和慢病管理需求,宣称“辅助降血脂”“缓解体力疲劳”等功能需取得保健食品蓝帽子认证。同步开展毒理学试验,证明每日摄入量下的长期食用安全性。定价策略上,可比同类功能性饮料高出合理溢价空间,凸显技术含量附加值。

联系佳味添成

联系佳味添成 官方微信

官方微信 网站地图

网站地图